Comprehensive Guide to Metal Fabricators and Die Casting Components Manufacturers at DeepMould

In the rapidly evolving world of manufacturing, the role of metal fabricators cannot be overstated. As the market demands increasingly complex and high-performance components, the expertise of die casting components manufacturers becomes vital to achieving precision, durability, and cost-efficiency. At DeepMould, we stand at the forefront of this industry, providing cutting-edge solutions tailored to diverse industrial needs.

Why Metal Fabricators Are Pivotal in Modern Manufacturing

Metal fabricators serve as the backbone of manufacturing industries, translating raw materials into functional, reliable components used across automotive, aerospace, electronics, and consumer goods sectors. Their expertise encompasses a wide range of processes—welding, cutting, bending, and assembling—each essential for producing precision-engineered parts. High-quality metal fabrication ensures that end products meet stringent safety standards, performance benchmarks, and aesthetic requirements.

The significance of metal fabricators grows even more prominent when considering the complex, high-precision die casting components required in today's technologically advanced applications. Effective fabrication unlocks enhanced product performance, reduces manufacturing costs, and accelerates time-to-market for innovative products.

DeepMould: Your Premier Metal Fabricator and Die Casting Components Manufacturer

DeepMould has established itself as a leader in the domain of metal fabricators, specializing particularly in the manufacturing of die casting components. Our commitment to excellence, technological innovation, and customer-centric solutions makes us the ideal partner for businesses seeking high-quality, reliable, and cost-effective manufacturing services.

Core Competencies of DeepMould in Metal Fabrication

- Advanced Casting Technologies: Utilizing hot chamber and cold chamber die casting methods to produce complex metal parts with tight tolerances.

- Precision Machining: Ensuring components meet detailed specifications through state-of-the-art CNC machining and finishing processes.

- Material Expertise: Working with a wide variety of metals, including aluminum, zinc, magnesium, and copper alloys, to suit specific application requirements.

- Rapid Prototyping & Customization: Offering quick turnaround for custom die casting components to meet unique project needs.

- Strict Quality Control: Implementing comprehensive inspection procedures at every stage to guarantee defect-free products.

The Importance of Choosing the Right Die Casting Components Manufacturers

Selecting a reliable die casting components manufacturer is critical to ensuring the success of your projects. The right partner enhances product performance, minimizes defects, and supports your business with innovative solutions. Here’s why DeepMould is the optimal choice:

- Industry Experience and Technical Expertise: Our team has decades of experience in die casting, enabling us to handle projects of varying complexities seamlessly.

- High-Quality Materials: We source premium-grade metals that guarantee strength, corrosion resistance, and high-performance standards.

- Advanced Manufacturing Facilities: Our investment in modern equipment allows us to produce complex, precision-engineered die casting components.

- Cost Efficiency and Competitive Pricing: Our optimized processes ensure affordability without compromising quality.

- Exceptional Customer Support: From design consultation to after-sales service, we prioritize our clients’ satisfaction at every phase.

The Process Workflow of DeepMould as Leading Metal Fabricators

Our comprehensive process encompasses every stage of metal fabrication with meticulous attention to detail:

- Design & Engineering: Collaborating with clients to develop detailed CAD models, ensuring manufacturability and performance optimization.

- Prototyping & Tooling: Creating precision molds to validate design integrity before mass production.

- Die Casting: Employing state-of-the-art die casting machines to produce complex components with high dimensional accuracy.

- Post-Casting Processes: Performing trimming, deburring, surface finishing, and heat treatments to enhance product quality.

- Quality Control & Inspection: Conducting rigorous inspections, including X-ray, CMM measurements, and visual checks to ensure compliance with standards.

- Delivery & After-sales Support: Providing timely delivery and ongoing support to maintain long-term client relationships.

Advantages of Partnering with DeepMould for Your Die Casting Components

By choosing DeepMould, your business benefits from numerous advantages:

- Superior Quality Products: Our components meet international standards such as ISO, ASTM, and RoHS.

- Innovation-Driven Solutions: Leveraging the latest technologies to develop complex, lightweight, and durable parts.

- Sustainable Manufacturing: Implementing eco-friendly processes to reduce waste and energy consumption.

- Flexible Production Volumes: Capable of handling both small batch prototypes and large-scale manufacturing.

- Global Reach: Serving clients worldwide, ensuring rapid communication and logistics support.

Industries That Rely on High-Quality Die Casting Components

Die casting components manufacturers like DeepMould supply essential parts across various sectors:

- Automotive: Engine components, transmission cases, and interior parts.

- Aerospace: Structural components that require high strength-to-weight ratios.

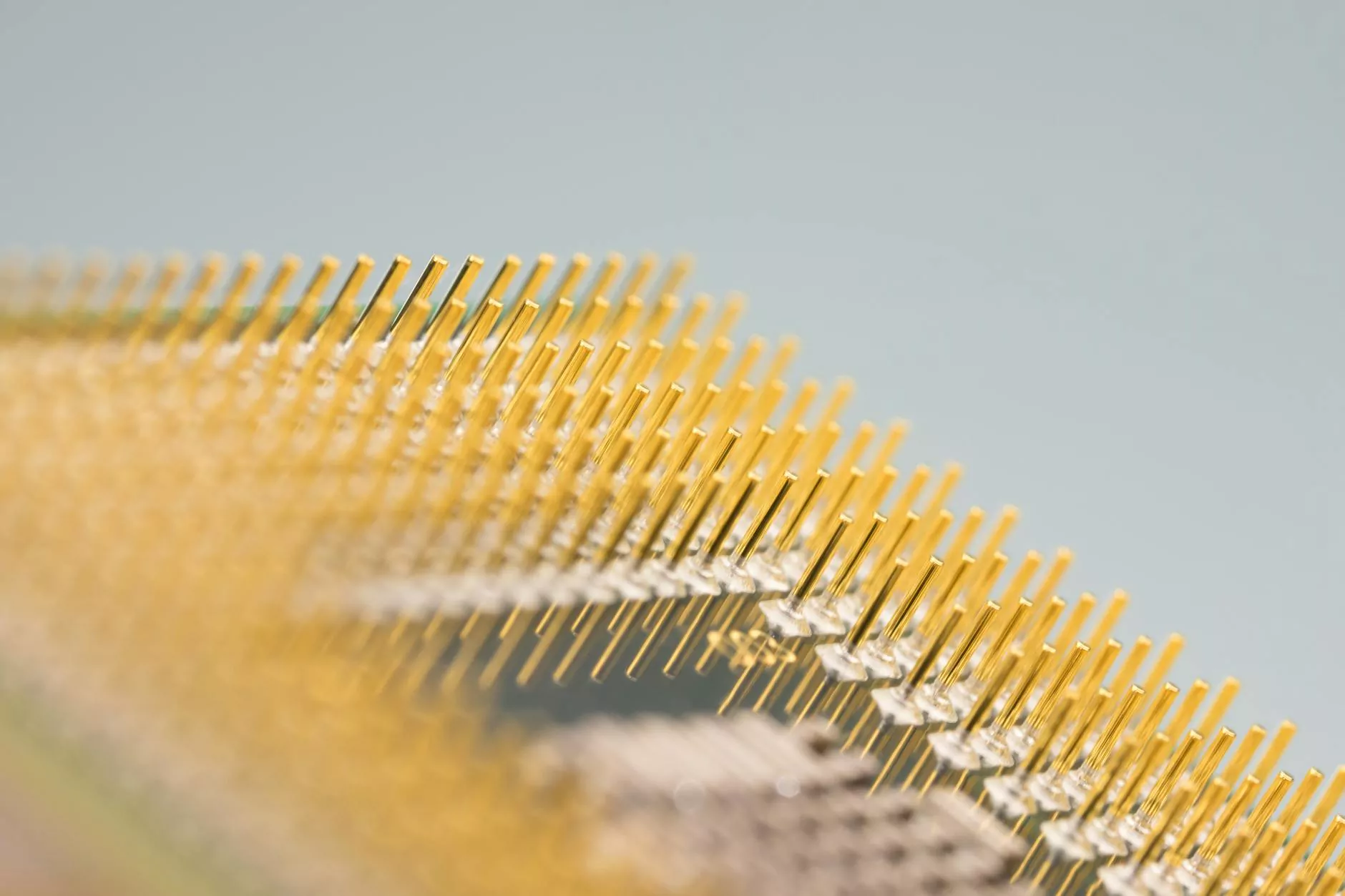

- Electronics: Connectors, housings, and heat sinks with precise specifications.

- Consumer Goods: Household appliances, fixtures, and decorative items.

- Industrial Equipment: Machinery parts, tools, and safety components.

Future Trends in Metal Fabrication and Die Casting

With technological advancements continuously shaping the industry, metal fabrication and die casting are evolving rapidly. Key trends include:

- Automation and Industry 4.0: Increased integration of robotics and IoT for smarter manufacturing processes.

- Lightweighting: Development of high-strength, lightweight metal alloys to improve fuel efficiency and performance.

- 3D Printing Integration: Combining additive manufacturing with traditional die casting for rapid prototyping and complex geometries.

- Sustainability Efforts: Focus on eco-friendly materials and waste reduction to meet environmental standards.

- Customization & Flexibility: Increasing demand for bespoke components tailored to specific client needs.

Why DeepMould Is Your Trusted Partner for Die Casting Components Manufacturing

As a leading metal fabricator and die casting components manufacturer, DeepMould offers unmatched quality, innovation, and reliability. Our dedicated teams and advanced facilities ensure that every product surpasses expectations. Whether your project requires intricate designs, critical tolerances, or high-volume production, we are equipped to deliver exceptional results.

Contact DeepMould Today for Premium Metal Fabrication Solutions

Join numerous satisfied clients who rely on DeepMould for their die casting and metal fabrication needs. We are committed to turning your concepts into precision-engineered components that empower your business to thrive in competitive markets. Reach out to us to discuss your project requirements and discover how our expertise can help you achieve manufacturing excellence.