Understanding the Crucial Role of the Crankshaft in Engines: The Heart of Diesel Powerhouses

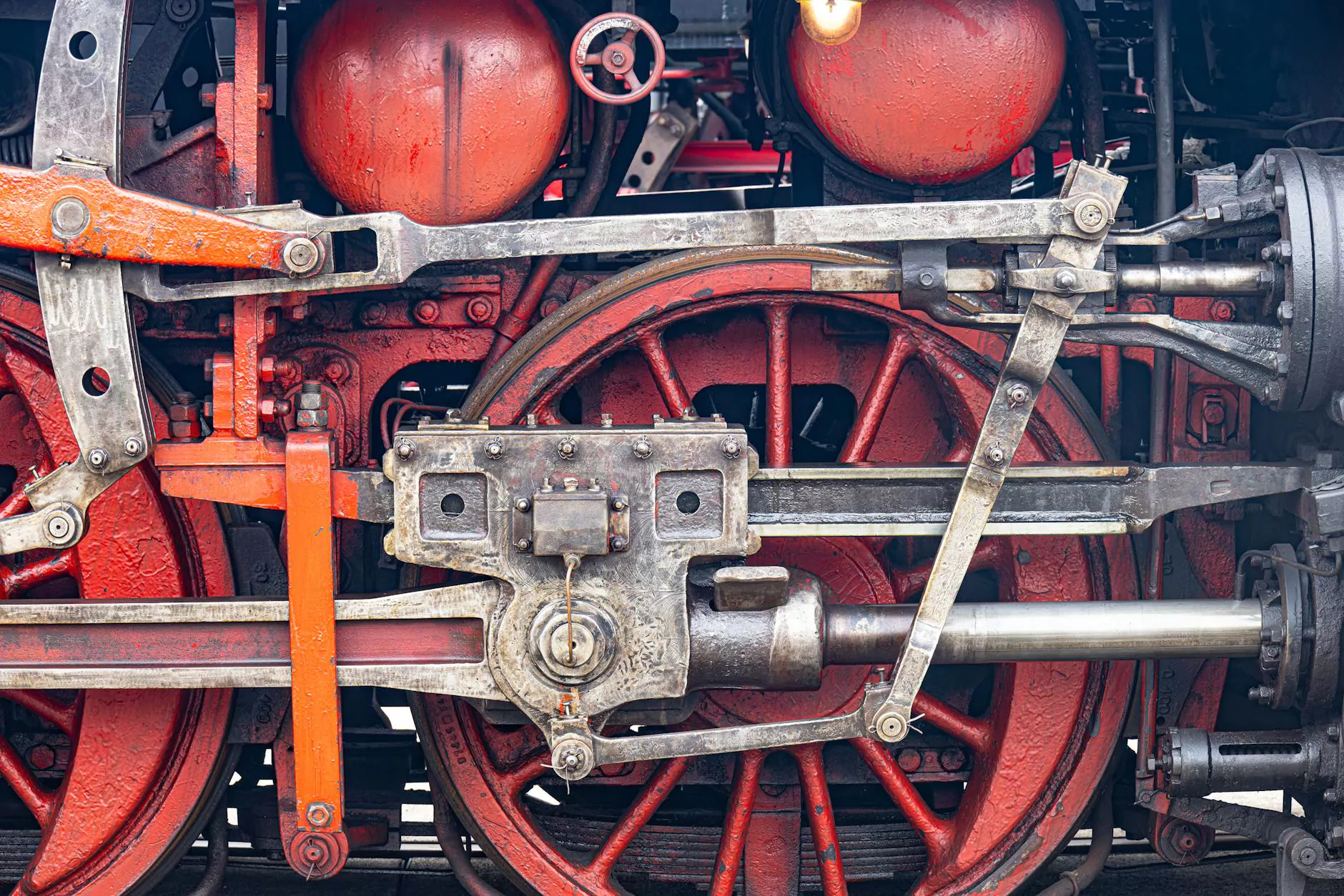

The crankshaft in engine is often regarded as the engine’s backbone—a vital component that transforms the linear motion of pistons into rotational force, thereby powering vehicles, machinery, and industrial equipment. As a core element within diesel engines and other internal combustion engines, the crankshaft's design, material integrity, and maintenance directly influence the overall performance, efficiency, and longevity of the engine. In this comprehensive guide, we delve into the intricate details of the crankshaft, its function, manufacturing process, common issues, and the significance of sourcing high-quality diesel engine parts from trusted spare parts suppliers such as client-diesel.com.

The Essentials of Crankshaft in Engines

The crankshaft in engine serves as the pivotal link that converts the pistons' reciprocating motion into rotational motion. This rotation ultimately drives the vehicle's wheels, machinery mechanisms, or industrial equipment. It is carefully engineered to withstand extreme forces, high temperatures, and continuous operation, emphasizing the importance of robustness in its design.

What Is a Crankshaft?

A crankshaft is a forged or cast metal component, usually made from forged steel, cast iron, or sometimes exotic alloys like stainless steel or titanium for high-performance applications. It features a series of offset sections called journals, connected by crankpins, and is equipped with counterweights to balance the rotational forces.

The crankshaft in engine interacts with other key components such as connecting rods, pistons, camshaft, and flywheel, forming an intricate mechanical system that drives the engine's power cycle efficiently.

Design and Construction of the Crankshaft: Engineering Precision

Designing a crankshaft requires meticulous attention to detail and a deep understanding of mechanical stresses and thermal expansion. The main sections of a crankshaft include:

- Main Journals: Support the crankshaft in the engine block and allow rotation around the main bearings.

- Crank Pins or Rod Journals: Connect to connecting rods, converting reciprocating motion into rotational motion.

- Counterweights: Balance the crankshaft during rotation to minimize vibrations.

- Gear or Pulley Attachments: For timing gears, oil pumps, and other accessories.

Material Selection and Manufacturing Processes

The choice of material is critical to ensure durability and performance. High-grade forged steel alloys are preferred for their strength-to-weight ratio and fatigue resistance. The manufacturing process typically involves:

- Casting or Forging: Initial formation of the crankshaft, with forging offering superior strength and grain structure alignment.

- Machine Machining: Precision machining of journals, crankpins, and bearing surfaces to tight tolerances.

- Heat Treatment: Processes such as quenching and tempering to enhance hardness and toughness.

- Balancing and Inspection: Critical steps to ensure smooth operation and adherence to specifications.

The rigorous manufacturing process results in a crankshaft that can withstand the demanding environments typical of diesel engines and other heavy-duty applications.

Importance of the Crankshaft in Diesel Engines

In diesel engines, which operate under higher compression ratios and generate substantial forces, the crankshaft in engine must exhibit exceptional durability and precision. Its performance directly affects key aspects such as:

- Power Output: Efficient conversion of piston movement to rotational energy determines engine power.

- Fuel Efficiency: Smooth operation minimizes energy losses, leading to better fuel economy.

- Engine Longevity: Proper balancing and material quality prevent premature wear or failure.

- Vibration Reduction: Well-designed crankshafts reduce engine vibrations, enhancing comfort and safety.

Common Issues and Troubleshooting of Crankshafts

Despite high manufacturing standards, crankshafts in engine can encounter issues over time due to various factors. Identifying and addressing these problems is crucial for maintaining engine health:

Typical Problems

- Crankshaft Cracks or Fractures: Usually caused by fatigue, overheating, or sudden mechanical shocks.

- Worn or Damaged Journals: Result from inadequate lubrication or contamination.

- Vibration and Unusual Noises: Indicate imbalance or misalignment.

- Misfire or Power Loss: Often linked to crankshaft bearing failure or damage.

Regular maintenance, high-quality spare parts, and timely replacements can mitigate these issues, ensuring continuous engine performance.

Choosing High-Quality Crankshafts and Spare Parts from Reliable Suppliers

To ensure engine durability and optimal performance, sourcing the right crankshaft and related diesel engine parts from trusted spare parts suppliers like client-diesel.com is essential. High-quality OEM parts come with guarantees of material integrity, precise manufacturing, and compatibility with specific engine models.

- OEM vs. Aftermarket Parts: OEM parts ensure perfect fit and durability, while reputable aftermarket parts may offer cost-effective alternatives without compromising quality.

- Supplier Reputation: Look for suppliers with proven track records, transparent sourcing, and strong customer reviews.

- Warranty and Support: A reliable supplier provides warranty coverage and technical guidance.

Expert Tips for Maintaining Your Crankshaft and Diesel Engine

Proper maintenance practices can extend the life of your crankshaft in engine and overall engine health:

- Regular Oil Changes: Use high-quality lubricants to reduce friction and prevent wear.

- Routine Inspections: Check for signs of wear, cracks, or unusual vibrations.

- Alignment and Balancing: Ensure the crankshaft is correctly aligned and balanced during assembly or after repairs.

- Timely Replacement of Worn Parts: Replace bearings, seals, or other components when indicated to prevent further damage.

- Maintain Proper Cooling: Prevent overheating that can weaken or deform the crankshaft.

The Future of Crankshaft Technology and Diesel Engine Parts

Advancements in material sciences, manufacturing technologies like additive manufacturing, and innovative design concepts are shaping the future of crankshaft in engine development. These innovations aim to create stronger, lighter, and more efficient components capable of withstanding the rigors of modern diesel engines.

Additionally, integration with smart sensors and diagnostic tools allows for predictive maintenance, minimizing downtime and optimizing performance.

Conclusion: Unlocking Power with High-Quality Crankshafts and Diesel Engine Parts

The crankshaft in engine remains a fundamental element that determines the success and longevity of diesel engines used across automotive, industrial, and marine sectors. Its design complexity, material choice, and maintenance dictate the engine's ability to deliver reliable power consistently.

For businesses and individual operators seeking top-tierdiesel engine parts, partnering with reputable spare parts suppliers like client-diesel.com guarantees access to OEM quality components, expert support, and long-term value.

Invest in your engine’s future by prioritizing quality, precision, and proper maintenance—your crankshaft in engine is the heart that keeps your machinery or vehicle moving forward.